近半年

52000

44500

近1年

52000

44500

近3年

75000

44500

近6年

80000

44500

近10年

80000

41000

查看更多

近半年

52000

44500

近1年

52000

44500

近3年

75000

44500

近6年

80000

44500

近10年

80000

41000

查看更多

查看更多

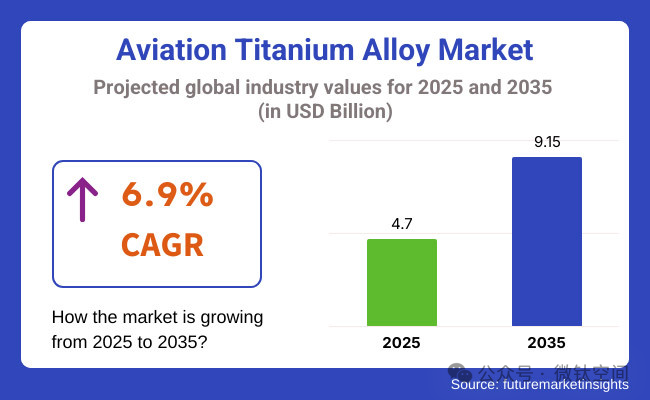

The aviation titanium alloy industry is poised to surge at a steady CAGR of 6.9% between the forecast period between 2025 and 2035. The market is anticipated to hold a market share of USD 4.7 billion in 2025 and is likely to reach a value of USD 9.15 billion.

在 2025 年至 2035 年的预测期内,航空钛合金行业将以 6.9% 的复合年增长率稳步增长。预计 2025 年该市场的市场份额将达到 47 亿美元,并可能达到 91.5 亿美元的价值。

In 2024, the industry for aviation titanium alloys saw consistent growth due to rising aircraft production, growing demand for lightweight and fuel-efficient materials, and development in additive manufacturing.

2024年,由于飞机产量增加、对轻量化和节油材料的需求不断增长以及增材制造技术的发展,航空钛合金行业将持续增长。

Major aerospace producers, such as Boeing and Airbus, stepped up their purchase of titanium alloys, especially for new-generation aircraft models. Supply chain disruptions continued, especially due to geopolitical tensions and volatility in raw material supply, which resulted in periodic price fluctuations. However, the demand was still strong as airlines concentrated on fleet renewal and sustainability.

波音和空客等主要航空航天制造商加大了对钛合金的采购力度,尤其用于新一代飞机。供应链中断持续存在,尤其受地缘政治紧张局势和原材料供应波动的影响,导致价格周期性波动。然而,由于航空公司专注于机队更新和可持续发展,钛合金需求依然强劲。

The industry is set to keep growing in 2025. It is expected to experience increased utilization of sophisticated manufacturing methods like 3D printing, which maximizes the use of titanium alloys and minimizes waste. Research and development spending will fuel innovation, resulting in the development of high-performance alloys with enhanced strength-to-weight ratios.

2025年,钛合金行业预计将持续增长。预计该行业将更多地采用3D打印等先进制造技术,这将最大限度地利用钛合金,并最大限度地减少浪费。研发支出将推动创新,从而开发出强度重量比更高的高性能合金。

Moreover, as defense budgets are on the rise in several nations, demand for titanium alloys used in military aircraft and unmanned aerial vehicles (UAVs) will increase.

此外,随着一些国家国防预算的增加,军用飞机和无人机(UAV)中使用的钛合金的需求将会增加。

各国情况分析

United States

From 2025 to 2035, the USA aviation titanium alloy industry is anticipated to grow at a 7.4% CAGR. The aerospace and defense sector is also a positive factor for the industry, with companies such as Boeing, Lockheed Martin, and Northrop Grumman using more titanium in next-generation aircraft.

美国

预计2025年至2035年,美国航空钛合金行业的复合年增长率将达到7.4%。航空航天和国防领域也为该行业带来了积极影响,波音、洛克希德·马丁和诺斯罗普·格鲁曼等公司将在下一代飞机中使用更多钛合金。

These requirements for DFARS compliance mean domestic titanium production stays first on the list for aerospace manufacturers, minimizing dependence on overseas suppliers. Additive manufacturing and higher government spending on military aircraft such as UAVs and fighter jets to bolster demand with high-performance titanium alloys.

这些符合DFARS标准的要求意味着,本国钛合金生产仍是航空航天制造商的首要任务,从而最大限度地减少了对海外供应商的依赖。增材制造技术的发展以及政府在无人机和战斗机等军用飞机上的支出增加,将刺激高性能钛合金的需求。

FMI opines that the United States aviation titanium alloy sales will grow at nearly 7.4% CAGR through 2025 to 2035.

FMI认为,2025年至2035年期间美国航空钛合金销量将以近7.4%的复合年增长率增长。

United Kingdom

The UK is anticipated to grow at a 6.5% CAGR through the forecast period, which is slightly slower than the global average. The country’s aerospace sector, which includes the defense contractors BAE Systems and Rolls-Royce, is a key factor in titanium alloy demand, especially in aircraft engines and structural parts.

英国

预计英国在预测期内的复合年增长率为6.5%,略低于全球平均水平。英国的航空航天业(包括国防承包商BAE系统公司和劳斯莱斯)是钛合金需求的关键因素,尤其是在飞机发动机和结构部件方面。

Trade uncertainties due to Brexit have disrupted supply chains, but partnerships with USA and European aerospace companies offer stability. Pioneering research into advanced titanium alloys with improved efficiency and recyclability are fostered and driven by the UK government’s push for sustainable aviation, including hybrid-electric aircraft.

英国脱欧带来的贸易不确定性扰乱了供应链,但与美国和欧洲航空航天公司的合作带来了稳定性。英国政府大力推动可持续航空发展(包括混合动力飞机),推动并推动了对效率更高、可回收性更强的先进钛合金的开创性研究。

FMI opines that the United Kingdom aviation titanium alloy sales will grow at nearly 6.5% CAGR through 2025 to 2035.

FMI认为,2025年至2035年期间,英国航空钛合金供应量将接近6.5%的复合年增长。

France

France is set to post a 6.8% CAGR between 2025 and 2035, owing to its strong civil and military aerospace industries. The French airline industry is one of the biggest consumers of titanium alloys used in aircraft, including the A350 and next-generation hydrogen-powered aircraft, as per the report.

法国

得益于法国强大的民用和军用航空航天工业,法国在2025年至2035年间的复合年增长率预计将达到6.8%。报告显示,法国航空业是飞机钛合金的最大消费行业之一,其应用领域包括A350和下一代氢动力飞机。

The French defense sector further fuels demand, as fighter jets require titanium, which Dassault Aviation is increasingly reliant on. Positive government incentives for aerospace R&D and growing investments in sustainable aviation technologies will propel the industry's expansion, but dependency on Russian titanium continues to be a threat.

法国

法国国防工业进一步刺激了钛金属需求,因为战斗机需要钛金属,而达索航空对钛金属的依赖日益加深。法国政府对航空航天研发的积极激励措施以及对可持续航空技术不断增长的投资将推动该行业的扩张,但对俄罗斯钛金属的依赖仍然是一个威胁。

FMI opines that French aviation titanium alloy sales will grow at nearly 6.8% CAGR through 2025 to 2035.

FMI 认为,2025 年至 2035 年期间,法国航空钛合金销量将以近 6.8% 的复合年增长率增长。

Germany

Germany's aviation titanium alloy industry will grow at 6.7% CAGR, lower than the global average. The country’s aerospace industry, underpinned by Airbus activities and important suppliers, needs titanium for high-performance aircraft parts.

德国 德国航空钛合金行业的复合年增长率将达到6.7%,低于全球平均水平。受空客业务及其重要供应商支撑的德国航空航天业需要钛合金来制造高性能飞机部件。

Titanium alloy demand is bolstered by the government's emphasis on technology innovation, particularly lightweight materials. Germany is also investing heavily in hydrogen aviation as well as electric propulsion systems, which is providing new ways for titanium to be used in new aircraft designs. But its growth in the industry may be at risk due to global supply chain challenges.

政府对技术创新(尤其是轻量化材料)的重视,提振了钛合金的需求。德国还在氢动力航空和电力推进系统方面投入巨资,这为钛合金在新型飞机设计中的应用提供了新的途径。但由于全球供应链的挑战,钛合金在该行业的增长可能面临风险。

FMI opines that German aviation titanium alloy sales will grow at nearly 6.7% CAGR through 2025 to 2035.

FMI认为,2025年至2035年间,德国航空钛合金销量将以近6.7%的复合年增长率增长。

Italy

Italy will expand at 6.3% CAGR, among the slowest growing industries across Europe. Demand for titanium alloys is largely driven by Leonardo S.p.A., Italy's largest aerospace company, for both commercial and defense purposes.

意大利

意大利的复合年增长率将达到6.3%,是欧洲增长最慢的行业之一。钛合金的需求主要由意大利最大的航空航天公司莱昂纳多公司(Leonardo S.p.A.)推动,用于商业和国防用途。

The dependence on imported raw materials complicates the issue, even as the country reaps the benefits of collaborations with European aircraft manufacturers. Government initiatives to modernize Italy’s aerospace sector and increase domestic production capabilities will sustain demand, but geopolitical tensions and economic uncertainties could stifle more rapid growth.

尽管意大利从与欧洲飞机制造商的合作中获益良多,但对进口原材料的依赖使问题更加复杂。意大利政府为实现航空航天业现代化和提升国内生产能力而采取的举措将维持需求,但地缘政治紧张局势和经济不确定性可能会抑制更快速的增长。

FMI opines that Italian aviation titanium alloy sales will grow at nearly 6.3% CAGR through 2025 to 2035.

FMI 认为,2025 年至 2035 年期间意大利航空钛合金销量将以近 6.3% 的复合年增长率增长。

South Korea

The South Korean aviation titanium industry is expected to grow at 7.1% CAGR, leading most of Europe. Korean aerospace firms such as Korea Aerospace Industries (KAI) are also ramping up their titanium consumption on fighter jets, helicopters, and space applications.

韩国

韩国航空钛合金行业的复合年增长率预计将达到7.1%,领先于欧洲大部分地区。韩国航空航天工业公司(例如韩国航空宇宙工业公司,KAI)也在加大其在战斗机、直升机和航天应用领域的钛合金消耗量。

The South Korean government has made a major financial commitment to indigenous aircraft programs like the KF-21 fighter jet, which needs sophisticated titanium components and parts. Joint ventures with international aerospace firms, together with a significant drive towards indigenous production of aerospace materials, will provide additional impetus to industry growth.

韩国政府已为KF-21战斗机等国产飞机项目投入了巨额资金,而该项目需要先进的钛合金零部件。与国际航空航天公司建立合资企业,并大力推进航空航天材料的国产化,将为行业增长提供更多动力。

FMI opines that South Korea aviation titanium alloy sales will grow at nearly 7.1% CAGR through 2025 to 2035.

FMI认为,2025年至2035年期间韩国航空钛合金销量将以近7.1%的复合年增长率增长。

Japan

Japan’s aviation titanium alloy industry will maintain the global average growth of 6.6%. Japan has a long history of aerospace development, with both Mitsubishi Heavy Industries and Kawasaki Heavy Industries involved in aircraft manufacturing.

日本

日本航空钛合金行业将保持全球6.6%的平均增长率。日本航空航天发展历史悠久,三菱重工和川崎重工均涉足飞机制造。

Japan is a top producer and exporter of titanium and has a steady supply for its domestic aerospace industry. The government is pouring money into new materials for next-generation aircraft, including supersonic and hydrogen-powered planes. Demand for titanium alloys is further bolstered by robust defense spending and alliances with the USA

日本是全球最大的钛生产国和出口国,为国内航空航天工业提供稳定的钛供应。日本政府正在大力投资下一代飞机的新材料,包括超音速飞机和氢动力飞机。强劲的国防开支以及与美国的联盟进一步提振了对钛合金的需求。

FMI opines that the Japan aviation titanium alloy sales will grow at nearly 6.6% CAGR through 2025 to 2035.

FMI认为,2025年至2035年期间日本航空钛合金销量将以近6.6%的复合年增长率增长。

China

China is estimated to have a CAGR of around 7.8%, making it one of the fastest-growing aviation titanium alloy industries. The country’s fast growth in commercial and military aviation also fuels demand, with COMAC creating new aircraft like the C919 and CR929.

中国

中国航空钛合金产业的复合年增长率预计约为7.8%,是增长最快的国家之一。中国商用和军用航空的快速发展也刺激了钛合金的需求,中国商飞正在打造C919和CR929等新型飞机。

China’s titanium sector is one of the largest in the world, ensuring efficient supply of availability for domestic manufacturers. Growth will also be further driven by government initiatives aimed at reducing dependence on Western aerospace suppliers and increasing domestic aircraft production.

中国钛行业是全球最大的钛行业之一,确保了国内制造商的高效供应。政府旨在减少对西方航空航天供应商的依赖并提高国内飞机产量的举措也将进一步推动钛行业增长。

Furthermore, the Tianwen-1 Mars Rover has the potential to expand the industry through specific customer preferences in titanium alloys, as China’s space industry is becoming an ever-growing demand customer.

此外,随着中国航天工业成为一个不断增长的需求客户,天问一号火星探测器有可能通过满足客户对钛合金的特定偏好来扩大该行业。

FMI opines that the China aviation titanium alloy sales will grow at nearly 7.8% CAGR through 2025 to 2035.

FMI认为,2025年至2035年期间中国航空钛合金销量将以近7.8%的复合年增长率增长。

Australia & New Zealand

The jet titanium alloy industry in Australia and New Zealand is estimated to grow at a CAGR of 6.2%, which is slightly less than the global average. Best-selling aircraft such as fighter jets, helicopters, and UAVs, are being actively acquired under defense procurement programs, driving the industry in Australia.

澳大利亚和新西兰

澳大利亚和新西兰的喷气式飞机钛合金行业预计以6.2%的复合年增长率增长,略低于全球平均水平。战斗机、直升机和无人机等畅销飞机正在国防采购计划下积极采购,推动澳大利亚的钛合金行业发展。

RAAF and cooperation with USA aerospace companies also keep the demand for titanium parts alive. Although smaller than the Australian industry, New Zealand's aerospace sector is a growing economy with expanding satellite manufacturing and UAV development. Although demand is stable, the low domestic titanium production in both countries means they depend on imports.

澳大利亚皇家空军以及与美国航空航天公司的合作也保持了对钛部件的需求。尽管新西兰的航空航天业规模不及澳大利亚,但随着卫星制造和无人机研发的不断扩大,新西兰的航空航天业正在蓬勃发展。尽管需求稳定,但两国国内钛产量较低,这意味着它们依赖进口。

FMI opines that the Australia-NZ aviation titanium alloy sales will grow at nearly 6.2% CAGR through 2025 to 2035.

FMI 认为,2025 年至 2035 年期间,澳大利亚-新西兰航空钛合金销量将以近 6.2% 的复合年增长率增长。

免责声明:钛谷交易网发布的原创及转载内容,仅供客户参考,不作为决策建议。原创内容版权归钛谷交易网所有,转载需取得钛谷交易网书面授权,且钛谷交易网保留对任何侵权行为和有悖原创内容原意的引用行为进行追究的权利。转载内容来源于网络,目的在于传递更多信息,方便学习与交流,并不代表钛谷交易网赞同其观点及对其真实性、完整性负责。